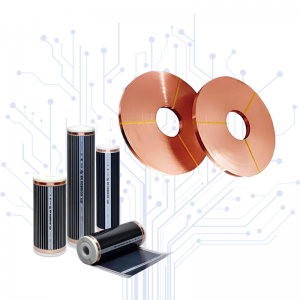

Foile ea Koporo e Mehelehileng

Selelekela sa Sehlahisoa

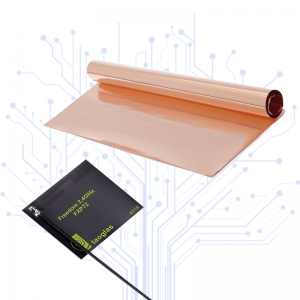

Koporo ke motsoako oa koporo le zinki, e tsejoang haholo e le koporo ka lebaka la 'mala oa eona o mosehla oa khauta. Zinki e koporong e etsa hore thepa e be thata le ho hanela hoho khohlela, athe thepa le yona e na lee ntle matla a ho thapolla. Foile ea koporo e hlahisoang keTŠEPE EA CIVEN e na le qetello e ntle ea bokaholimo, sebopeho sa lakane e bataletseng le botsitso bo botle. Foil ea koporo e atisa ho sebelisoa indastering ea mekhabiso ka lebaka la ponahalo ea eona ea khauta, e le thepa e sireletsang kapa e matlafatsang ka lebaka la ho thatafala ha eona le ho hanyetsa ho hoholo ha tšusumetso, le e le sesebelisoa sa ho thibela ho hoholo ha letlalo.gasket thepaka lebaka la ho se tsofale ha yona. Koporo e boetse e sebediswa hangata e le thepa ya ho futhumatsa ya motlakase ka lebaka lamotlakasethepa ea ho hanyetsa. Ka lebaka la sebopeho se chitjasebopeho ea e phutholohilengkoporo foil, boemo bo bonolo le bo thata bo ka laoloa ke ts'ebetso ea ho annealing, e leng se etsang hore e tšoanelehe haholoanyane bakeng sa mefuta e mengata ea lits'ebetso.CIVEN METEAL e ka boela ea hlahisa lifoile tsa koporo ka botenya le bophara bo fapaneng ho latela litlhoko tsa bareki, ka hona ho fokotsa litšenyehelo tsa tlhahiso le ho ntlafatsa katleho ea ts'ebetso.

Matlotlo a 'Mele

Botenya:8.5g/cm3

Ho tsamaisa motlakase (20 °C): 27% IACS

Ho tsamaisa mocheso (20 °C): 120W/(m °C)

Modulus e tenyetsehang: 105000N/mm2

Koefficient ea katoloso ea mocheso (20-300 °C) 20 X 10 -6 °C -1

Litlhaloso li fumaneha (mm)

| Botenya | Bophara | Bohale | BotenyaMamello

| Bophara Mamello |

| 0.01~0.15 | 4~200 | O、1/4H、1/2H、H | ± 0.003 | Toler ea Bophara± 0.1li-ance |

Matlotlo a Mekaniki

| Bohale | JIS Bohale | Ho tenyetseha Matla Rm/N/mm2 | Tekanyo A50/% | Bothata ba HV |

| M | O | 350~410 | ≥ 25 | 80~120 |

| Y4 | 1/4H | 375~445 | ≥ 15 | 105~145 |

| Y2 | 1/2H | 385~460 | ≥ 12 | 120~165 |

| Y | H | 450~510 | ≥ 5 | 135~185 |

Tlhokomeliso: Re ka fana ka lihlahisoa tse nang le thepa e 'ngoe ho latela litlhoko tsa bareki.

Kopo:

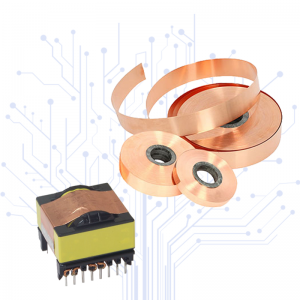

Foil ea radiator e nepahetseng haholo ke thepa ea bohlokoa tlhahisong ea likoloi, mochini oa lihoai, mechini ea merafo, mechini ea boenjiniere, terene ea disele, kaho ea likepe,jenereithara sete.

Tekanyetso e Jarollotsoeng (ea morao-rao)

| Lichaba | Nomoro e Tloaelehileng | Lebitso le Tloaelehileng |

| Chaena | GB/T2059--2000 | MAEMO A NAHA A CHINA |

| Japane | JIS H3100:2000 | MAQEPHE, LIPOLEITE LE LITŠOANTŠISO TSA KOPORO LE KOPORO |

| usa | ASTM B36/B 36M -01 | TLHAHISO E TLWAELEHILENG BAKENG SA KOPO, POLEITE, LATE, TLHALOSO LE BAR E METHELENG |

| Jeremane | DIN-EN 1652:1997 | POLEITE, LAETE, MOQHWA LE LIDIKGOLO TSA KOPORO LE KOPORO BAKENG SA MORERO OA KAKARETSO |

|

| DIN-EN 1758:1997 | SEKOTO SA LITŠOANTŠISO TSA KOPORO LE KOPORO BAKENG SA LIFREIME TSA LITAELO |

| SEMI | SEMI G4-0302 | TLHAHISO-PELE BAKENG SA DISEBEDISWA TSA LEADFRAME TSA POTOLOHO E HLAHISITSWENG TSE SEBELISANG TLHAHISONG YA LEADFRAME TSE HLAHISITSWENG KA SETAMPI |