Liboto tsa potoloho tse hatisitsoeng tse feto-fetohang ke mofuta o kobehang oa boto ea potoloho e entsoeng ka mabaka a 'maloa.Melemo ea eona holim'a liboto tsa potoloho ea setso e kenyelletsa ho fokotseha ha liphoso tsa kopano, ho ba le botsitso maemong a thata, le ho khona ho sebetsana le litlhophiso tse rarahaneng tsa elektroniki.Liboto tsena tsa potoloho li entsoe ka ho sebelisa foil ea koporo ea electrolytic, e leng thepa e bonahalang ka potlako e le e 'ngoe ea bohlokoa ka ho fetisisa indastering ea elektronike le ea puisano.

Kamoo Flex Circuits e Etsoang Kateng

Flex Circuits e sebelisoa ho tsa elektroniki ka mabaka a fapaneng.Joalokaha ho boletsoe pejana, e fokotsa liphoso tsa kopano, e mamella tikoloho haholoanyane, 'me e khona ho sebetsana le lisebelisoa tsa elektroniki tse rarahaneng.Leha ho le joalo, e ka boela ea fokotsa litšenyehelo tsa basebetsi, ea fokotsa boima ba 'mele le litlhoko tsa sebaka,' me ea fokotsa lintlha tsa khokahanyo tse eketsang botsitso.Bakeng sa mabaka ana kaofela, li-circuits ke e 'ngoe ea likarolo tsa elektroniki tse batloang haholo indastering.

A tenyetsehang hatisitsoeng potolohoe entsoe ka likarolo tse tharo tse kholo: Li-conductors, Likhomaretsi, le Li-insulators.Ho itšetlehile ka sebopeho sa li-circuits tsa flex, lisebelisoa tsena tse tharo li hlophisitsoe hore hona joale li phalle ka tsela eo moreki a e batlang, le hore e sebelisane le likarolo tse ling tsa elektronike.Lisebelisoa tse tloaelehileng haholo bakeng sa sekhomaretsi sa flex circuit ke epoxy, acrylic, PSAs, kapa ka linako tse ling ha ho letho, ha li-insulators tse sebelisoang hangata li kenyelletsa polyester le polyamide.Hona joale, re thahasella haholo li-conductor tse sebelisoang lipotolohong tsena.

Le hoja lisebelisoa tse ling tse kang silevera, carbon, le aluminium li ka sebelisoa, thepa e sebelisoang haholo bakeng sa li-conductor ke koporo.Foil ea koporo e nkuoa e le lisebelisoa tsa bohlokoa bakeng sa tlhahiso ea li-circuits tse feto-fetohang, 'me e hlahisoa ka litsela tse peli: rolling annealing kapa electrolysis.

Kamoo Lifola Tsa Koporo li Etsoang Kateng

Foil ea koporo e annealede hlahisoa ka ho roala lilakane tse futhumetseng tsa koporo, ho li fokotsa le ho etsa bokaholimo ba koporo bo boreleli.Lipampiri tsa koporo li tlas'a mocheso o phahameng le likhatello ka mokhoa ona, ho hlahisa sebaka se boreleli le ho ntlafatsa ductility, bendability, le conductivity.

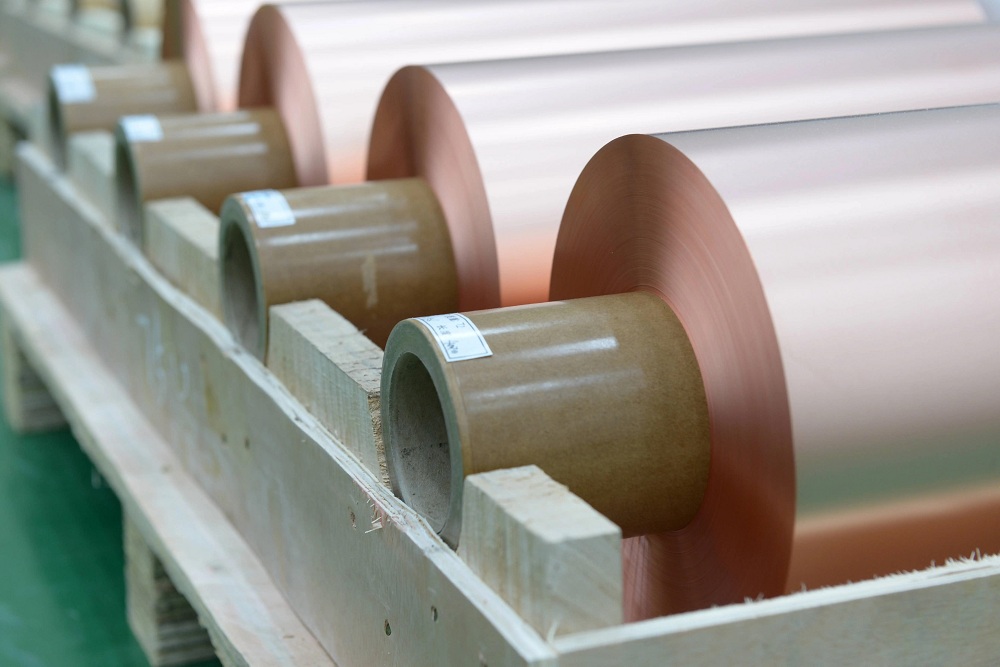

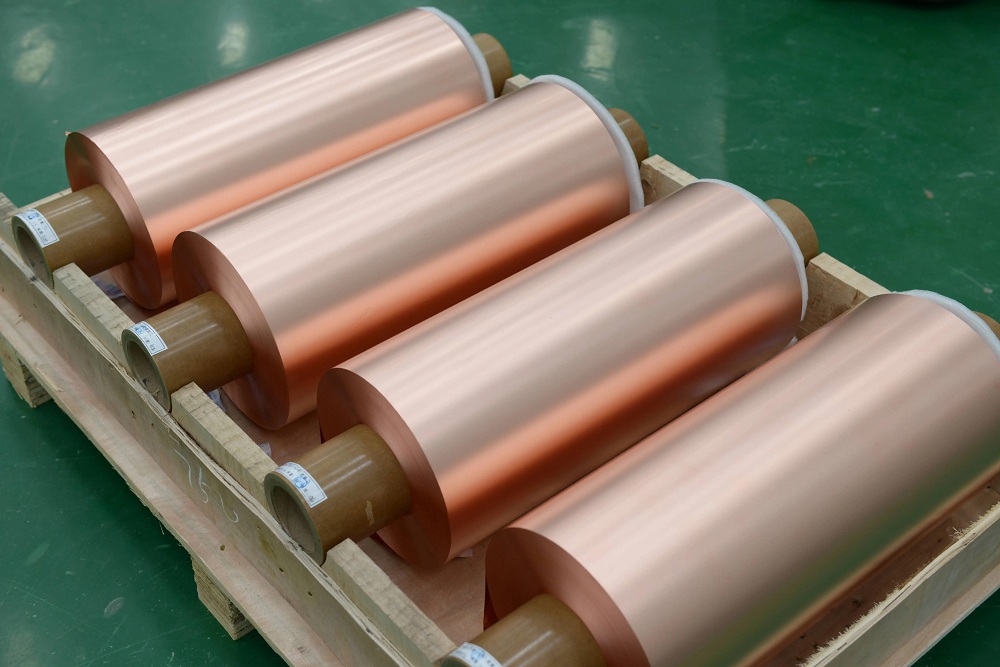

Ho sa le joalo,electrolytic koporo foil e hlahisoa ka ho sebelisa mokhoa oa electrolysis.Tharollo ea koporo e entsoe ka sulfuric acid (e nang le li-additives tse ling ho itšetlehile ka litlhaloso tsa moetsi).Joale sele ea electrolytic e tsamaisoa ka tharollo, e ntan'o etsa hore li-ion tsa koporo li theohe 'me li lule holim'a cathode.Li-additives li ka boela tsa ekeletsoa tharollong e ka fetolang thepa ea eona ea ka hare hammoho le ponahalo ea eona.

Ts'ebetso ena ea electroplating e tsoela pele ho fihlela drum ea cathode e tlosoa tharollo.Moropa o boetse o laola hore na foil ea koporo e tla ba botenya hakae, kaha moropa o potolohang ka potlako o boetse o hohela pula e ngata, e tenya foil.

Ho sa tsotellehe mokhoa oo, lifolakha tsohle tsa koporo tse hlahisoang ho tsoa ho mekhoa ena ka bobeli li ntse li tla phekoloa ka phekolo ea tlamahano, phekolo ea ho hanyetsa mocheso, le phekolo ea botsitso (anti-oxidation) ka mor'a.Liphekolo tsena li nolofalletsa lifolakha tsa koporo hore li khone ho tlamahane hantle ho sekhomaretsi, li khone ho mamella mocheso o amehang ho thehoeng ha potoloho ea 'nete e hatisitsoeng, le ho thibela oxidation ea foil ea koporo.

Rolled Annealed vs Electrolytic

Hobane mokhoa oa ho theha foil ea koporo ea foil ea koporo e kentsoeng le ea electrolytic e fapane, e boetse e na le melemo le melemo e fapaneng.

Phapang e kholo lipakeng tsa lifolakha tse peli tsa koporo ke ho latela sebopeho sa tsona.Foil ea koporo e kentsoeng e tla ba le sebopeho se otlolohileng mocheso o tloaelehileng, ebe morphs e fetoha sebopeho sa kristale sa lamellar ha se tlas'a khatello e phahameng le mocheso.Ho sa le joalo, foil ea koporo ea electrolytic e boloka sebopeho sa eona se seholo ka mocheso o tloaelehileng le likhatello tse phahameng le mocheso.

Sena se baka phapang ho conductivity, ductility, bendability, le litšenyehelo tsa mefuta e 'meli ea foil ea koporo.Hobane lifeele tsa koporo tse kenngoeng hangata li boreleli, li khona ho tsamaisa 'me li loketse mehala e menyenyane.Li boetse li na le li-ductile tse ngata 'me ka kakaretso li kobeha ho feta foil ea koporo ea electrolytic.

Leha ho le joalo, mokhoa o bonolo oa mokhoa oa electrolysis o tiisa hore foil ea koporo ea electrolytic e na le litšenyehelo tse tlaase ho feta li-foil tsa koporo tse pota-potiloeng.Leha ho le joalo, ela hloko hore e ka 'na ea e-ba khetho e tlaase bakeng sa mela e menyenyane, le hore e na le khanyetso e mpe ho feta ea lifola tsa koporo tse kentsoeng.

Qetellong, li-foil tsa koporo tsa electrolytic ke khetho e ntle ea theko e tlaase e le li-conductor ho potoloho e hatisitsoeng e bonolo.Ka lebaka la bohlokoa ba potoloho ea flex ho lisebelisoa tsa elektronike le liindasteri tse ling, le eona, e etsa hore lifola tsa koporo tsa electrolytic e be thepa ea bohlokoa hape.

Nako ea poso: Sep-14-2022